Quick Look: Inventory management is the process of organizing and managing your inventory from the day you purchase it to when it sells. This guide will discuss leading inventory management techniques, formulas, and tips for managing inventory.

What is Retail Inventory Management?

Your inventory is one of the most valuable assets at your c-store or gas station. Because you’ve invested in products that make sense for your customers, it’s only natural to make sure you provide the right products in the right quantities at the right time. And if you don’t, your inventory may become more of a liability and negatively impact your cash flow.

With proper retail inventory management, you’ll know:

- How much of each item you have in stock, what to reorder and when to do so

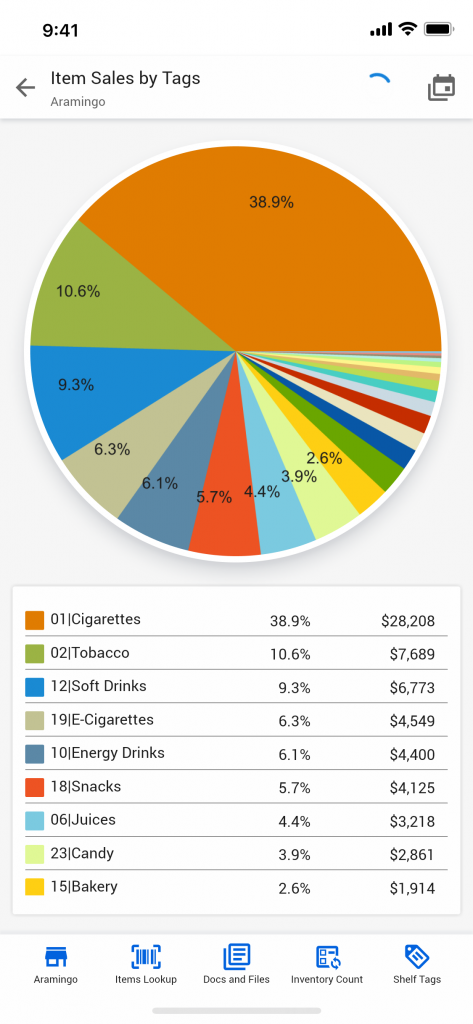

- Your best and worst selling items so you can decide what to keep and what to stop offering

- If you have sufficient inventory storage

Your ultimate goal should be to use inventory control tools and methods to understand customer behavior and sales patterns to make better business decisions throughout the year.

Tip: According to the U.S. Census Bureau, U.S. manufacturers and retailers were holding $1.33 of inventory for every $1 in sales in July 2020. When you practice effective inventory management, you can improve your inventory-to-sales ratio for the better — stationary inventory doesn’t do anything for your business.

Types of Inventory

Small business inventory tracking may look different in different industries; however, how you manage your c-store inventory will boil down to four common types of inventory:

- Centralize your records. List all products you offer in one place. You should provide every detail of each product you sell — be as specific as you can. Additionally, you may want to add product descriptions to help employees find them easily.

- Count your inventory regularly to ensure accuracy. Account for shrinkage, returns, damaged goods, and defects to avoid making any errors. If you already have an inventory management system in place, double-check your records for accuracy either quarterly or annually (at a minimum). Additionally, update your inventory system when you sell new items, or a vendor changes your costs or delivery terms. And be sure to clearly define who is responsible for tracking and monitoring inventory and when it should be done.

Helpful: You can use different inventory counting methods at your c-store or gas station, including physical counting and cycle counting. Discover the differences and other best practices to keep your inventory accurate. - Clearly define the location of each item you sell. If you have one c-store or gas station, this process is pretty simple — your stock is either on display or in your stockroom. But if you have multiple stores or gas stations, you’ll carry inventory at different locations, at a warehouse, or distribution center. Consider using RFID tags, bar codes, and labels to help you locate your inventory quickly.

- Combine sales and inventory data for easier reporting and better decision-making. You can see which items are turning over fastest and when (and how) to reorder products, offer promotions, or discount items in your c-store or grocery.

- Create a consistent purchasing process. That way, you can review your inventory data and place orders in a timely manner, avoiding stock outages or seasonal trends. Prioritize orders based on the product’s popularity, profitability, and lead time. And if you automate your purchasing process, you can trigger alerts to help you reorder more efficiently.

- Use markdowns and promotions based on product demand and profitability. By doing so, you’ll improve your cash flow position and have enough inventory available to meet customer demand.

- Establish a receiving process for your inventory. First, verify incoming orders and enter items accurately into your inventory system. Then, check each delivery against the purchase order to ensure you’re getting what you paid for from your vendors. Once you confirm your order, follow up immediately with your vendors if you find any damage, mistakes, or shortfalls.

- Determine how to handle customer returns. Be sure your employees know the process you want them to take when a customer returns a damaged or defective item to your c-store or gas station: return it to the supplier, dispose of it, or prepare it for resale.

- Define guidelines for dead stock (damaged items, incorrect deliveries, and leftover seasonal products). Any excess inventory you have ties up capital and can negatively impact your profitability. Create guidelines that outline when to ship an item back to the vendor, donate it to a needy organization, recycle it, or throw it away.

- Identify inventory KPIs and track them regularly. Monitor key performance indicators (KPIs) to help gauge the success of your inventory process, including profitability, inventory value, sell-through rate, and turnover rate. Make adjustments when needed to ensure you’re meeting your short and long-term business goals.

Inventory Management Methods for Retailers and Key Inventory Management Formulas

Using the appropriate inventory management method will help you maximize your profit by reducing costs, improving efficiency, and understanding what drives sales at your c-store or gas station. Here are six standard methods used to help determine inventory demand and their formulas:

- Inventory Turnover Rate measures how many times you’ve sold and replaced inventory over a specific time period, giving you insight into the overall efficiency of your c-store or gas station in getting through its inventory — the higher, the better. Here’s the formula:

Inventory Turnover = COGS/Average Inventory. - Sell-Through Rate compares the amount of inventory you receive to what you actually sell during a specific time period (often expressed as a percentage). You can use this rate to see if your investment in a product is working out as planned: a low rate means you either overpriced the product or bought too much, while a high rate means your price is too low or you underbought it. Here’s the formula:

Sell-Through Rate = (# of Sales / Stock On-Hand) x 100 - Days of Inventory Outstanding (DIO) measures how long your inventory takes to turn into sales. It’s a good way to measure your c-store or gas station against the industry standard — and whether you’re trending up or down. Here’s the formula:

DIO = (Avg Inventory Cost / COGS) x 365 - Safety Stock is your backup stock to meet unexpected customer demands or supply problems. Keep your eye on carrying costs, though. It would be best if you struck a balance between having enough inventory available to meet demand but not so much it puts a strain on your cash flow. Here’s the formula:

Safety Stock = (Max Daily Sales Volume x Max Lead Time in Days) – (Avg Daily Daily Sales Volume x Avg Lead Time in Days) - Reorder Point lets you know when to order new inventory. Just be sure you understand the lead time required for delivering new products so you can keep enough stock on hand to meet customer demand. Here’s the formula:

Reorder Point = (Lead Time in Days x Avg Daily Sales Volume) + Safety Stock - Economic Order Quantity (EOQ) helps you calculate how much inventory to order. It considers customer demand, ordering costs, and carrying costs to give you the most economical amount to order. Here’s the formula:

EOQ = √ 2 x (Demand x Ordering Costs) / Carrying Cost per Unit

Inventory Management Software for C-Stores and Gas Stations

Using the right technological solutions at your c-store or gas station will give you the data you need to manage your inventory effectively. Here are some software features to consider:

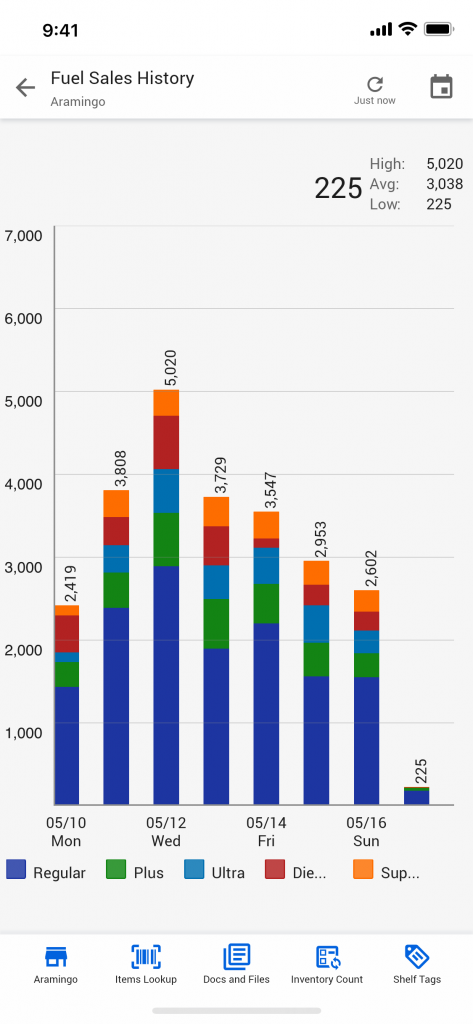

- Tracks inventory in real-time and syncs that information with your sales data

- Uses historical sales data to project future inventory needs

- Manages supplier data and allows you to create and send purchase orders to replenish your stock easily

- Allows you to access data anywhere you are 24/7

Take a look at some of the best solutions for inventory management for small businesses, such as c-store and gas stations:

- Handheld Scanners — a quick and easy way to record your manual inventory counts. Before you purchase a handheld scanner, consider the barcodes you use, plus battery life and durability.

Smart idea: Using Petrosoft’s handheld scanners, you’ll experience fewer human errors and reduce the hours spent counting inventory.

- Point-of-Sale (POS) System — automatically updates inventory as sales are completed. Using this real-time data in your back-office system, you’ll make smarter inventory management decisions. Additionally, you can provide an audit trail when investigating errors or theft.

Best bet: Petrosoft’s SmartPOS offers an easy-to-use POS system with analytics (including loss prevention), foodservice, back-office, loyalty, and forecourt integration options. It also integrates with industry partners for consistent pricing, optimal inventory levels, and customer satisfaction.

- Back-Office System — centralizes data into one easily accessible place, including your inventory, price book, reporting, promotions, lottery, buydowns, and more. Additionally, it should integrate with your POS system, accounting packages, fuel, merchandise, and data suppliers to further increase operational efficiency.

Try this: For optimal inventory management, invest in Petrosoft’s back-office system, CStoreOffice®. You can track current inventory, forecast future needs, and optimize your product mix to support revenue growth.

Inventory Management FAQs

Here are a few of the most asked questions we receive about inventory management:

Q: Does Petrosoft offer inventory management solutions?

A: Yes. We offer many different solutions to help maximize your profit using strong inventory control — from handheld scanners to SmartPOS software to our back-office system CStoreOffice®.

Q: What are retail inventory costs?

A: Inventory costs fall into three categories: ordering costs (or setup costs), carrying costs (or holding costs), and stockout costs (or shortage costs). You must pay careful attention to each as you manage your inventory so you can maximize your profitability.

Q: How do you track inventory in a convenience store?

A: While you can use manual processes (pen and paper) or online spreadsheets to track inventory, your best option is to use convenience store inventory software. You’ll know how much inventory you have on hand (in real-time) and minimize the chances of overselling or underselling your inventory.

Q: How are inventory levels monitored in c-stores and gas stations?

A: A comprehensive inventory online spreadsheet or automated system (such as Petrosoft’s CStoreOffice®) is essential to manage inventory across multiple sales channels. You can then purchase new inventory when needed (ideally based on reorder points), maintaining the right amount of inventory storage you need, and minimize shrinkage.

Q: What is a good inventory turnover ratio for retail stores?

A: A higher inventory turnover ratio typically indicates better performance and efficiency. For most retail stores, a good inventory turnover ratio falls between 5 and 10, which means you typically restock every couple of months. Calculate your inventory turnover ratio.

Q: What is retail inventory control?

A: Inventory control and inventory management are slightly different. Inventory control focuses on the products already in your inventory and where they’re located. It keeps your inventory organized so you can minimize costs and keep your products in excellent condition. On the other hand, inventory management includes all the business processes required for optimal product replenishment and forecasting. It ensures you have the right inventory in the right place at the right time and in the correct amount. Ultimately, you can improve your inventory management when you provide better inventory control.