Right-sized technology provides the critical competitive edge in the retail playing field, particularly among independents and chains. Today’s leading convenience store operators are maximizing their performance by leveraging technology in two interrelated areas of inventory management practice: optimal inventory levels, and a highly productive product mix. See how SG II Group built the infrastructure they needed to manage both their inventory and their bottom line.

Understand Convenience Store Industry Performance Benchmarks

In the quest to improve inventory performance, top c-store owners benchmark their performance against other top performers and adopt industry best practices. They also deploy technology to improve inventory volume and mix, while keeping margins at targeted levels.

The stakes are high because inventory inaccuracy usually leads to two undesirable outcomes: When popular items go out-of-stock, sales are lost and you risk losing customers in the long haul; and attempts to mitigate this risk with excess inventory or safety stock undercut financial performance by tying up precious cash.

In addition, ineffective management of product mix leads to problems essentially similar to overstocks. Slow-moving items and overstocks tie up capital, shelf-space and increase shrinkage and spoilage risk. For this reason, top c-store operators pay careful attention to turnover rates.

Although certain elements of order fulfillment may be out of the retailer’s control (like delivery schedules, case pack sizes and vendor assortment requirements), technology pinpoints areas where dollar-productive efficiencies are possible.

Create Benchmarks For Your C-Store Business

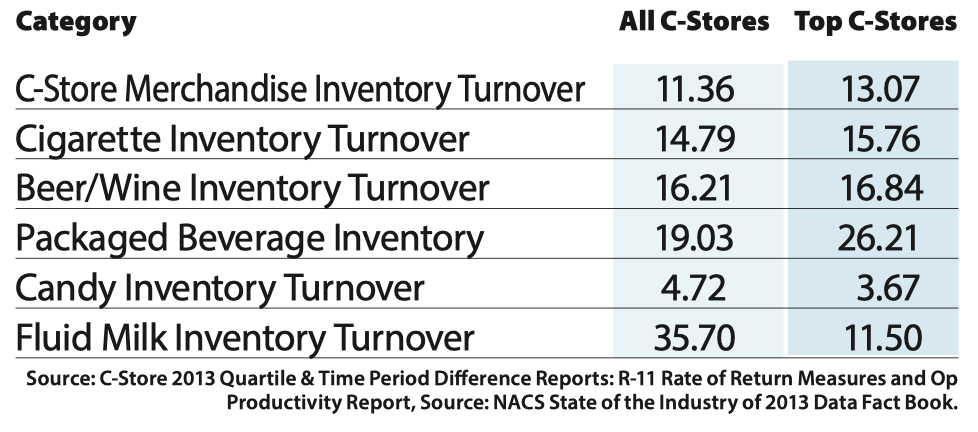

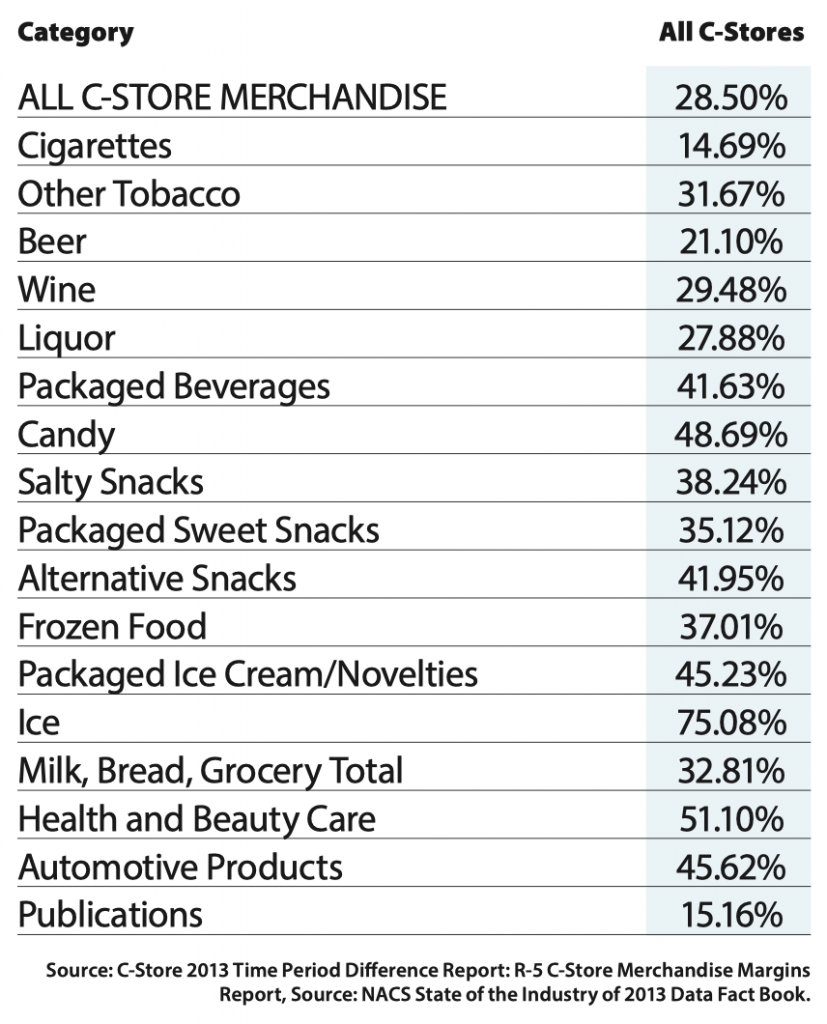

Single- and multi-store operators evaluate how their inventory is performing by calculating their inventory turnover ratio and profit margins by store and for categories, and then compare their performance against industry averages. For 2013, the National Association of Convenience Stores (NACS) reports the average c-store merchandise inventory turnover ratio was 11.36 times a year, but the top performing c-store operators had a much better average inventory turnover ratio of 13.07 times (Table 1). For 2013, NACS reports average c-store merchandise margins were 28.5% (Table 2).

Key Merchandise Categories

Use Technology Efficiently

Single and multi-store owners can decrease errors, overstocks and the discounting that cut into already slim margins through the smart application of inventory management technology. Pittsburgh-based SG II Group, for example, uses CStoreOffice®, the back-office solution on the Petrosoft Platform, to help build their intelligence, infrastructure and processes that enable territory and store managers to improve inventory performance and meet store GPM while increasing merchandise turnover (see story on next page). CStoreOffice® helps single and multi-store owners build that infrastructure.

Application Highlight: Inventory Management in Action: SG II Group

SG II Group, a Pittsburgh-based c-store operator with more than 20 stores, consistently delivers top performance with an average turnover ratio of 16.12. Its top performing stores report a 22.21 turnover ratio. The company also keeps its margins within a healthy range. To achieve this high level of performance, the company takes advantage of technology. SG II Group uses CStoreOffice®, Petrosoft’s cloud-based back-office solution, to keep inventory lean, producing the right mix and volume of inventory.

SG II Group also takes advantage of inventory forecasting to increase sales. Forecasting improves SG II Group’s financial performance by optimizing inventory. It also helps its Territory Manager to prioritize store visits, spending more time at stores with critical inventory issues, such as overstocks.

Their process of managing overstocks is straightforward—an imperative for independents and chains. SG II Group inputs an acceptable inventory range for each of its stores in CStoreOffice® based on past performance. It then runs forecast reports to identify stores that are overstocked. Next, it prioritizes store visits based on how critically the store is falling outside of that acceptable range. The company also uses stock movement reports to identify slow moving items, and moves dead items to a new location in the store or to another store, if the item is selling well at another location.

Where warranted, the company also creates price, “2 for 1,” or other discount promotions to quickly clear unwanted inventory, freeing up shelf space for better performing items. By using the forecasting features and reports to discover critical overstocks and slow moving items, SG II Group further increases its bottom line, as well as enhancing turnover ratio and spoilage reduction.

To keep profits healthy while moving a high volume of inventory, SG II Group also tracks GPM at the store, category and item level, which helps to pinpoint inventory issues. The company also quickly spots inventory purchase, fulfillment, or vendor invoicing errors with the GPM range feature, which blocks the acceptance of invoices that fall outside of the c-store owner’s acceptable GPM ranges. By discovering these errors in a timely way, SG II Group can investigate and quickly take corrective action with the manager, vendor or, in some cases, by adjusting the retail price to ensure that profit margins remain healthy.

SG II Group also uses the Petrosoft cloud-based technology platform in additional ways to improve inventory performance, such as: auditing the price book for accuracy, scanning inventory, performing monthly full-store item-level inventory counts, using the item shortage report and investigating the causes, counting high-risk items such as cigarettes every day and, in some cases, every shift by promo group or in total. The company also uses the system-generated merchandise orders report, a suggested order based on inventory levels and vendor delivery schedules, to help decrease manager order errors and overstocks.