Inventory management at your convenience store can make or break your c-store operation. The first step to gaining control over your c-store’s bottom line is to get an accurate view of your item-level inventory. It’s critical to use the data you gather to learn about convenience store inventory control and increase your c-store profits with dead inventory management, inventory placement, and shrinkage control.

Inventory Movement: Industry Averages

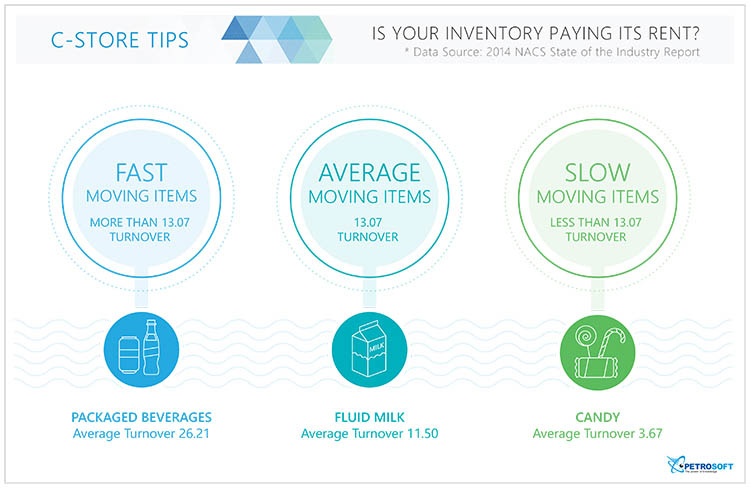

What can industry averages tell us about c-store inventory movement? According to the National Association of Convenience Stores (NACS) 2014 State of the Industry Report (SOI), the top-performing c-stores had an average inventory turnover of 13.07. High turnover, fast-moving categories for these top performers included packaged beverages (26.21), beer/wine (16.84), and cigarettes (15.76).

Convenience store operators can use this category-level data as a benchmark to see how well their operation is performing compared to the industry. However, your ability to perform efficient convenience store inventory management will allow you to become a top-performing operator.

Inventory Movement: The Importance of Item-level Inventory

With proper infrastructure, technology, and operational procedures, a c-store’s accurate item-level data can help you ensure that each inventory item on each shelf pays its rent. Whether in-store inventory items sell quickly with the risk of becoming out-of-stock (at an average rate), or slowly with the risk of becoming overstocked, this data can help you make the most of your c-store’s shelf space and inventory. How can you use this data effectively?

If an item is moving slowly, you can:

- Rotate or move the slow-moving item to another location in the store.

- Move the item to another store if it sells well at that location.

- Clear out dead items with promotions, freeing up space for higher performing inventory.

- Return the item to the vendor.

You can easily track your inventory at item-level by physically counting items or using a back-office technology system, such as Petrosoft’s CStoreOffice® (which also includes forecasting capabilities needed to optimize inventory).

Inventory Placement: Reducing Risk and Increasing Profitability

Managing inventory placement helps resolve inventory movement issues. If you’re not careful, you can lose thousands of dollars through item theft (shrinkage) and expiration (spoilage). In fact, according to the 2019 National Retail Security Survey, the industry’s average shrink rate of 1.38% has held steady over the past three years. Effective convenience store inventory control, whether using physical counts or a back-office system, will help keep your operation profitable. And placing some items strategically in the store will help boost sales. Here are some best practices to consider:

- Keep track of inventory at item-level.

- Place high theft (risk) items behind the counter or in the cashier’s line of sight.

- Place bestselling (high turnover) items toward the back of the store.

- Review inventory item expiration dates frequently.

- Periodically review the back-office system’s missing items reports.

- Regularly conduct physical (cycle) inventory counts and resolve discrepancies.

By having an accurate item-level count and timely inventory reports, you’ll increase your profits due to better dead inventory management, inventory placement, and shrinkage control.

To create consistency in monitoring your c-store’s daily inventory, use a cloud-based back-office solution, such as CStoreOffice®, to provide the infrastructure you need to make the most out of your inventory and shelf space and ultimately improve your bottom line.